Introduction of non-point pollution reduction facilities

Instructions and drawings that contain the reduction principle, structure, and specifications of non-point pollution reduction facilities

A. Definition of the non-point pollution source

Non-point pollution source refers to an emission source that discharges unspecified sewage pollutants from unspecified places such as urban area, roads, farmland, mountainous areas, and construction sites. <Article 2(2) of Environmental Law>

B. Types of pollutants

Soil, nutrients, bacteria and viruses, oil and grease, metals (lead, zinc, cadmium, copper, nickel, etc.), organic matter, herbicides, pesticides and fungicides and other impurities

C. Explanation for the reduction principle of non-point pollutant

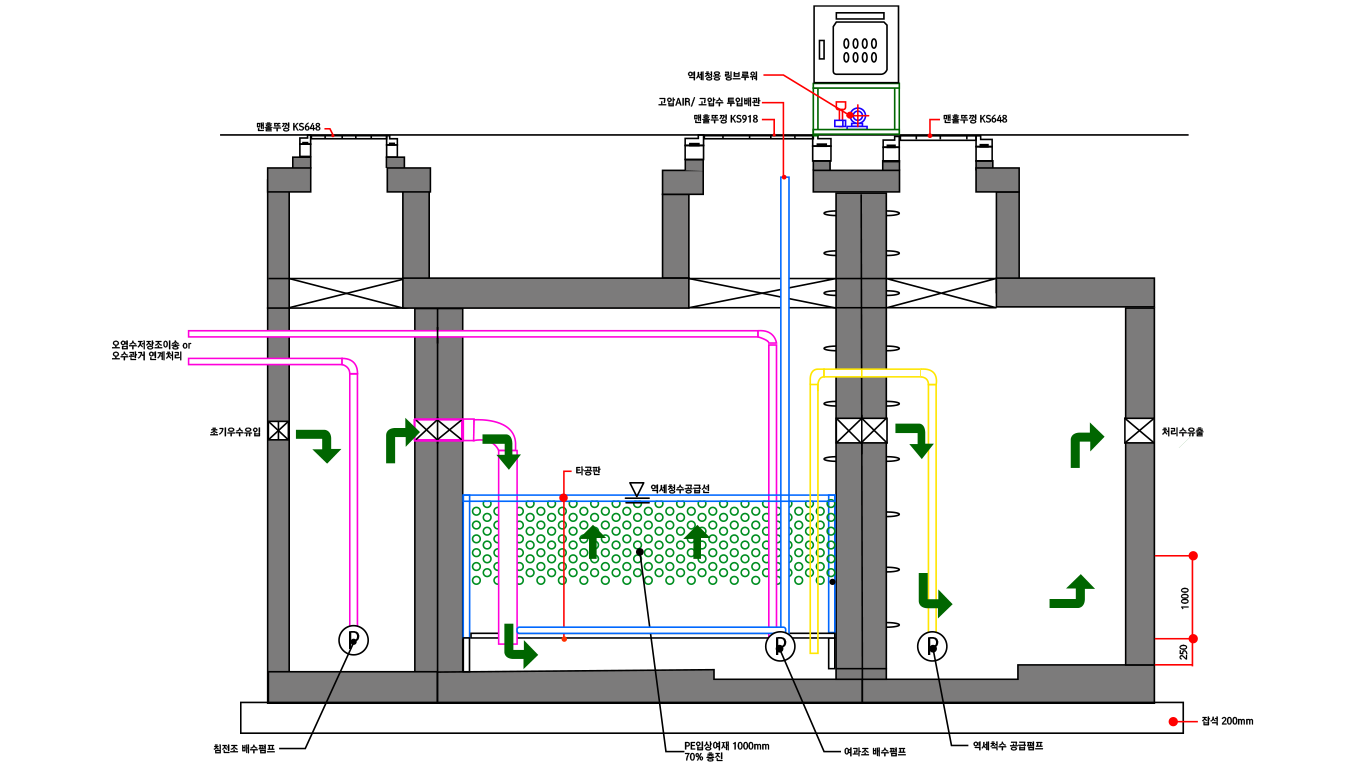

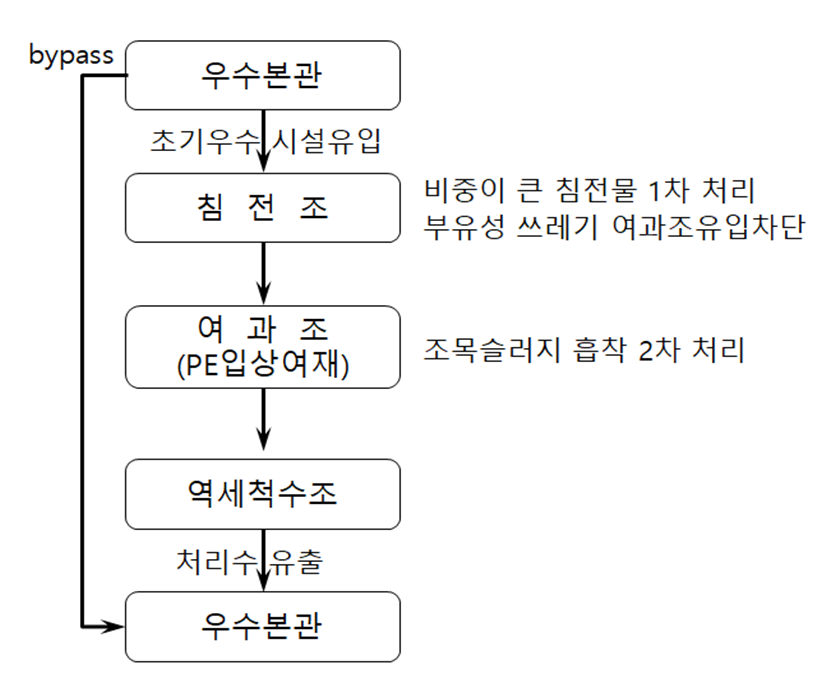

1) The principle that non-point pollution reduction facilities reduce non-point pollutants, schematic diagram and flow chart of facilities

2) Differentiated technical features from other non-point pollution reduction facilities

D. Structure and characteristics of non-point pollution reduction facilities

1) The principle that the non-point pollution reduction facility reduce pollution including the overall structure of the facility and the characteristics of the detailed structure inside the facility

E. Economy

- The filter provides a high-density (HDPE) granulous filter media with good efficiency and can be used semi-permanently (10 years)

- Has longer service life and superior backwashing compared to fiber filters

- There is no deformation unless otherwise heat is applied, and no need to change the filter media.

F. Convenience of maintenance

- ECOVISION21 (ECO-TYPE) filter material is designed for easy maintenance due to high-density (HDPE) and fluid formed in a round shape

- The filter is connected to the air line and can be backwashed, so it can be used semi-permanently after washing for about 5 minutes.

- Settling tank and filtration tank are easy to dredge sediment through vacuum suction (the operator does not need to enter the tank)

- The facility is designed to transfer the stagnant water to a sewage pipe or wastewater storage tank through a pump.

Filter applied